CSEC

Building Technology

Here we have a detailed summary of the complete CSEC Building Technology Syllabus:

Natural and Built Environment

Natural Environment

Natural Environment can be defined generally as all the living and nonliving things that occur naturally on earth. In other words, it has not been influenced by man.

Components of the Natural Environment

Atmosphere- The layer of gasses that envelops Earth is known as the atmosphere. It is mostly composed of oxygen (21%) and nitrogen (78%) with trace amounts of other gasses. Because it filters out dangerous UV rays from the sun, regulates temperature fluctuations, and produces oxygen, the atmosphere is necessary for life.

Geosphere- All of the Earth’s solid components, including rocks, minerals, and landforms, are referred to as the geosphere. It reaches the surface of the Earth from its core, covering the ocean floor, mountains, and valleys.

Ecosystem- A community of living things interacting with their natural surroundings is called an ecosystem. This encompasses microorganisms, plants, animals, and the soil, water, and air that surround them.

Built Environment

The built environment consists of all human-made structures and spaces that facilitate human activities. This includes various types of infrastructure designed to support everyday life.

Examples of the Built Environment:

- Buildings: Residential houses, office buildings, schools, hospitals, and shopping centers.

- Transportation Infrastructure: Roads, highways, bridges, railways, and airports.

- Public Spaces: Parks, plazas, and recreational areas.

- Utilities: Water supply systems, sewage systems, and electrical grids.

- Urban Areas: Cities, towns, and neighborhoods designed for living, working, and recreation.

Climate Change

Climate change refers to the change in the average conditions, such as temperature and rainfall over a long period of time.

Factors Influencing Climate Change

- Greenhouse Gas Emissions: Human activities, such as burning fossil fuels (coal, oil, and gas), release large amounts of carbon dioxide (CO₂), methane (CH₄), and nitrous oxide (N₂O) into the atmosphere. These gasses trap heat, causing the Earth’s temperature to rise.

- Deforestation: The removal of forests reduces the number of trees that can absorb CO₂, increasing the concentration of this greenhouse gas in the atmosphere.

- Industrial Activities: Factories and industrial processes emit various pollutants and greenhouse gasses, significantly contributing to climate change.

- Agriculture: Farming activities, including livestock production, release methane and nitrous oxide, both potent greenhouse gasses.

- Natural Factors: Volcanic eruptions, changes in solar radiation, and natural climate cycles can also influence the Earth’s climate, though their impact is much smaller compared to human activities.

Effects Of Climate Change

- Rising Temperatures: Global temperatures are increasing, leading to more frequent and intense heat waves.

- Melting Ice and Rising Sea Levels: Glaciers and ice sheets are melting, causing sea levels to rise and threatening coastal communities.

- Extreme Weather Events: Climate change is linked to more severe weather events, such as hurricanes, droughts, and heavy rainfall.

- Ecosystem Disruption: Changes in temperature and precipitation patterns affect ecosystems, leading to shifts in species distribution and the timing of biological events.

- Impact on Agriculture: Altered weather patterns can affect crop yields, leading to food shortages and increased prices.

- Human Health: Increased temperatures and extreme weather events can lead to health issues, such as heat-related illnesses and the spread of diseases.

Classification of Timber - Conifers & Deciduous

Definition of Timber

Timber refers to wood that has been processed for use in construction and carpentry. It can also denote trees cultivated specifically for this purpose.

Classification of Timber

Timber can be categorized into two primary types: conifers and deciduous trees.

Conifers

- Characteristics: Conifers are evergreen trees with needle-like or scale-like leaves. They produce cones and typically retain their leaves year-round.

- Examples: Pine, spruce, fir, and cedar.

- Wood Type: These trees yield softwood, which is generally lighter and easier to work with.

Deciduous

- Characteristics: Deciduous trees, also known as broadleaf trees, have wide leaves that fall off in autumn and regrow in the spring.

- Examples: Oak, maple, birch, and walnut.

- Wood Type: These trees produce hardwood, which is usually denser and more durable than softwood.

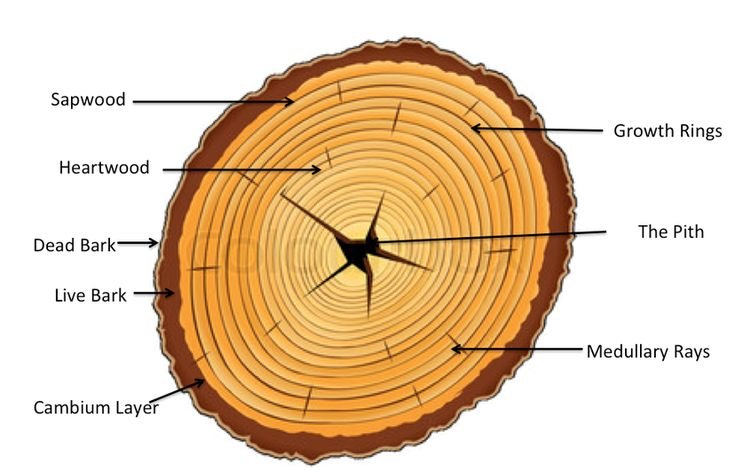

Cross Section of a Tree Trunk

A tree’s trunk can be seen in a cross section, displaying the different layers that each serve different purposes. These layers are visible from the outer bark to the deepest pith when a tree trunk is cut crosswise. The structure and purpose of each component of the tree can be better understood with the aid of this cross-sectional view.

Sapwood Function: The sapwood, also known as xylem, is the outermost layer of wood that carries water and nutrients from the roots to the leaves. It also provides structural support to the tree.

Heartwood Function: The heartwood is the central, older part of the tree trunk, made up of dead xylem cells. It offers additional strength and support and is typically darker and more resistant to decay.

Dead Bark Function: The dead bark, or outer bark, acts as a protective layer, shielding the tree from external threats like pests, diseases, and physical damage. It also helps minimize water loss.

Live Bark Function: The live bark, or phloem, is responsible for transporting nutrients, especially sugars produced by photosynthesis in the leaves, to other parts of the tree.

Cambium Layer Function: The cambium is a thin layer of living cells that generates new phloem and xylem cells. It is crucial for the tree’s growth in diameter.

Growth Rings Function: Growth rings, also called annual rings, are layers of wood produced each year. They can be used to determine the tree’s age and provide insights into the environmental conditions during each year of growth.

The Pith Function: The pith is the innermost part of the trunk, composed of soft, spongy cells. It stores and transports nutrients during the early stages of the tree’s growth.

Medullary Rays Function: Medullary rays are radial sheets or ribbons that extend vertically through the tree. They transport nutrients and water horizontally across the trunk and provide structural support.

Timber Seasoning

Timber seasoning is the process of drying timber appropriately in order to remove moisture from the wood wall’s cells.

Methods of Timber Seasoning

Natural Seasoning

Natural seasoning utilizes environmental conditions to dry timber. While it takes longer, it is cost-effective and eco-friendly.

- Air Seasoning: Timber is stacked to allow air to circulate around each piece. Depending on the wood type and climate, this process can take several months to a year. It is simple and inexpensive but requires ample space and time.

- Water Seasoning: Timber is submerged in water to remove the sap, then air-dried. This less common method can reduce the wood’s strength.

Artificial Seasoning

Artificial seasoning uses controlled environments to expedite the drying process. It is faster and more precise but can be more costly.

- Kiln Seasoning: Timber is placed in a kiln where temperature, humidity, and air circulation are controlled. This method can dry wood in days or weeks and is widely used in the industry.

- Chemical Seasoning: Timber is treated with chemicals to reduce moisture content. This method can be effective but may alter the wood’s properties.

- Electrical Seasoning: High-frequency electric currents are used to heat and dry the timber. This method is quick but can be costly and requires specialized equipment.

- Boiling: Timber is boiled in water for several hours to quickly remove moisture, then air-dried.

Wood-Working Joints

Woodworking joints are the techniques used to join two or more pieces of wood, creating strong and aesthetically pleasing structures.

Examples of Woodworking Joints

Butt Joint

- Description: The simplest joint where two wood pieces are joined end-to-end.

- Uses: Common in framing, basic furniture, and simple construction projects.

- Pros: Easy to create with minimal tools.

- Cons: Not very strong without reinforcement.

Miter Joint

- Description: Two wood pieces are cut at an angle (typically 45 degrees) and joined to form a corner.

- Uses: Ideal for picture frames, trim work, and decorative corners.

- Pros: Offers a clean, seamless appearance.

- Cons: Requires precise cutting and often needs reinforcement.

Dovetail Joint

- Description: Interlocking pins and tails are cut into the ends of two wood pieces.

- Uses: Used in drawer construction, fine furniture, and cabinetry.

- Pros: Extremely strong and visually appealing.

- Cons: Complex to create, requiring skill and precision.

Mortise and Tenon Joint

- Description: A tenon (projection) on one piece fits into a mortise (hole) on another piece.

- Uses: Common in table legs, chairs, and frames.

- Pros: Very strong and durable.

- Cons: Time-consuming to make and requires precise cutting.

Lap Joint

- Description: Two wood pieces overlap each other.

- Uses: Used in frames, furniture, and structural applications.

- Pros: Provides a large gluing surface and is relatively easy to make.

- Cons: Can be bulky and may need additional reinforcement.

Tongue and Groove Joint

- Description: One wood piece has a protruding tongue that fits into a corresponding groove on another piece.

- Uses: Common in flooring, paneling, and table tops.

- Pros: Provides a strong, tight fit.

- Cons: Requires precise milling and alignment

Pocket-Hole Joint

- Description: Screws are driven into angled holes to join two wood pieces.

- Uses: Used in cabinetry, furniture, and DIY projects.

- Pros: Quick and easy to make with a pocket-hole jig.

- Cons: Visible screw holes may need to be concealed.

Additional Information

- Purpose: Wood joints are crucial for creating strong, durable, and visually appealing wooden structures without relying solely on adhesives or fasteners.

- Selection: The choice of joint depends on the project’s specific requirements, including strength, appearance, and ease of construction.

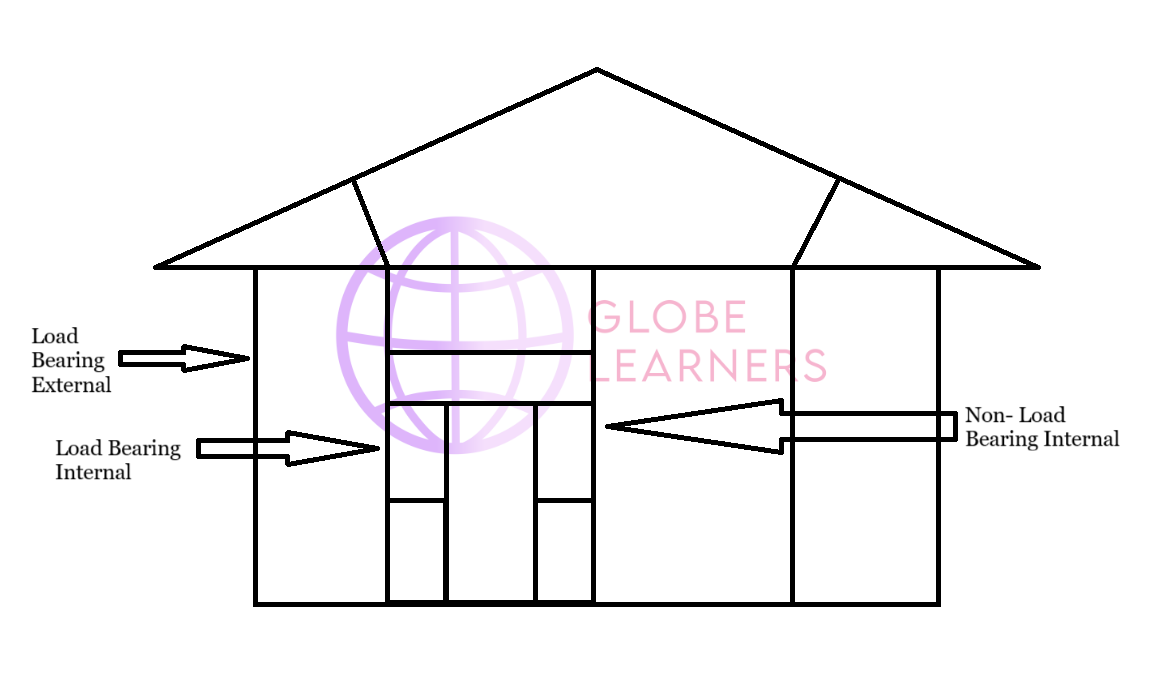

Walls, Roofs and Floors

Walls

Definition and Function:

Walls are essential structural components of a building that define spaces, provide privacy, and support other structural elements such as the roof and floors. They can also offer insulation, soundproofing, and fire resistance.

Types of Walls:

- Load-Bearing Walls:

- External Load- Bearing Walls: These are the perimeter walls of a building, designed to support significant structural loads from the roof and floors, and to withstand environmental pressures. They are typically constructed from robust materials like brick, stone, or concrete.

- Internal Load- Bearing Walls: Located within the building, these walls help distribute weight and support various structural elements, ensuring the structural integrity of the building.

- Non-Load-Bearing Walls:

- External Non- Load-Bearing Walls: Used primarily as part of the building envelope but not for structural support, these walls act mainly as weather or thermal barriers.

- Internal Non- Load-Bearing Walls: These are used to divide spaces inside a building and can be easily modified or relocated as they do not support any significant weight.

Materials:

- Load-bearing walls utilize durable materials such as brick, concrete, and stone.

- Non-load-bearing walls may use lighter materials like gypsum board, plywood, and glass.

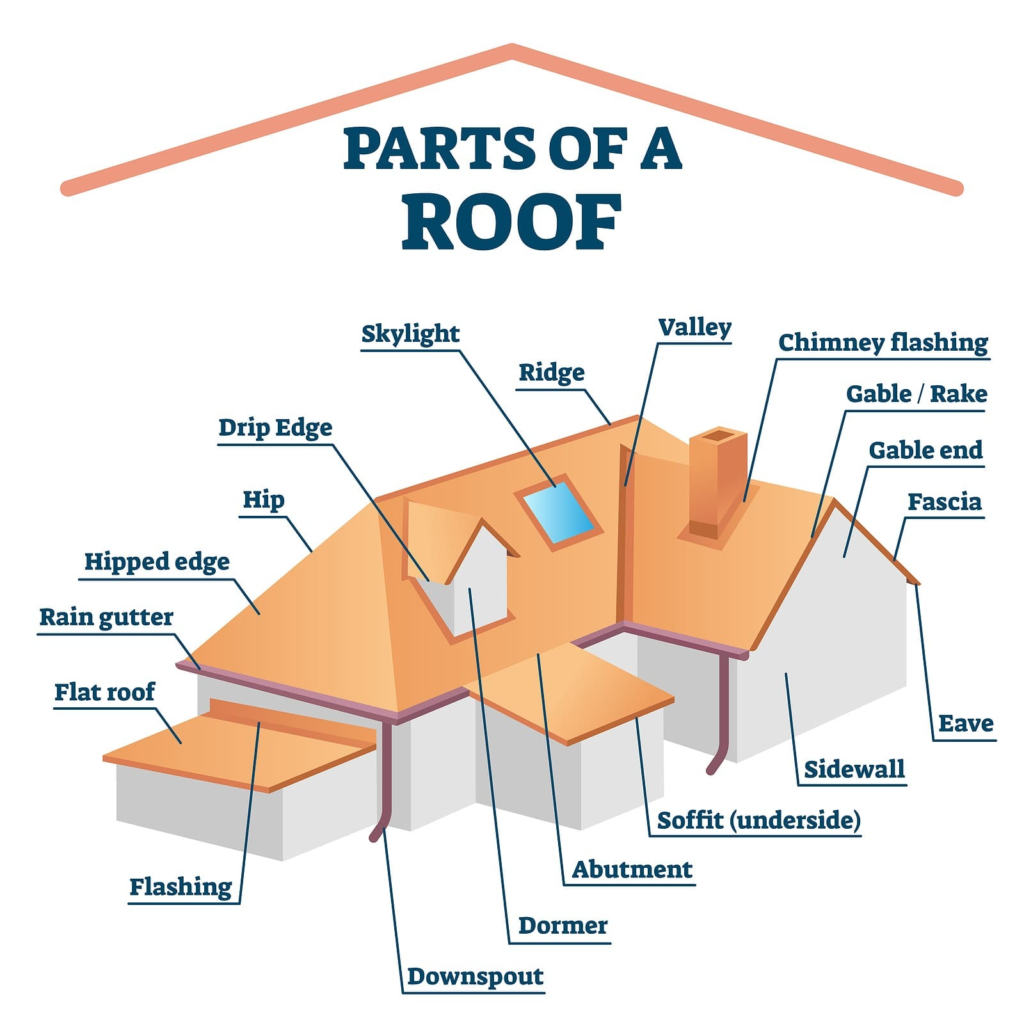

Roofs

Definition and Function:

The roof is the uppermost part of a building, designed to protect against the elements, provide thermal insulation, and contribute to the overall aesthetics and architectural style of the building.

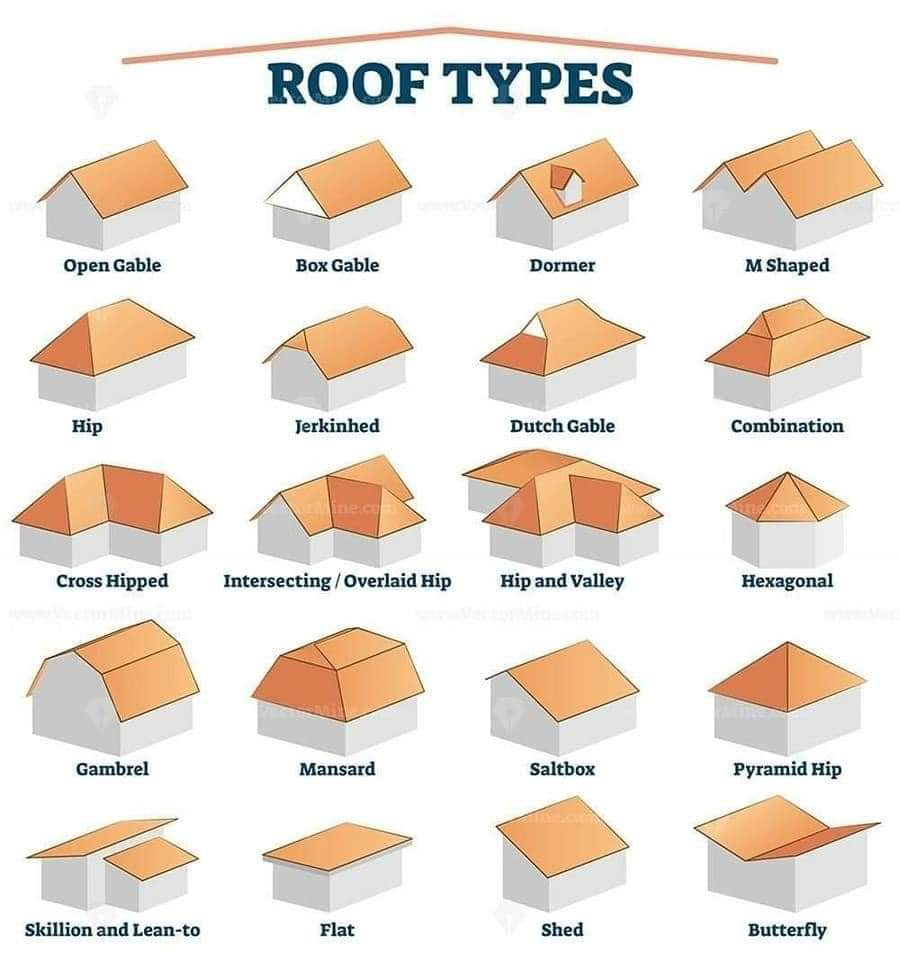

Types of Roofs:

- Flat Roofs: Common in commercial buildings, these roofs may have a slight pitch to facilitate water drainage.

- Pitched Roofs: These include gabled, hipped, and mansard roofs, all of which have sloped surfaces to enhance water runoff and increase attic space.

- Gabled Roofs: Characterized by a simple triangular shape, allowing for easier water runoff and more attic space.

- Hipped Roofs: Slope on all sides down to the walls, offering excellent stability and resistance to wind.

- Mansard Roofs: Feature both flat and sloped surfaces, providing additional living space under the roof.

Components:

- Trusses and Rafters: The structural framework that supports the roof cover.

- Decking/Sheathing: The layer attached to the trusses/rafters to cover the building.

- Underlayment: A water-resistant layer between the roof cover and the decking.

- Shingles or Tiles: The outermost layer, providing weather protection and aesthetic qualities.

Floors

Definition and Function: Floors form the lower bounding surfaces of rooms, providing a stable and durable surface for occupants and furniture. They also contribute to the building’s structural integrity and thermal insulation.

Types of Floors:

- Concrete Floors: Known for their strength and durability, suitable for various applications from residential to industrial.

- Wooden Floors: Include hardwood, engineered wood, and laminates, popular for their aesthetic appeal and warmth.

- Tiled Floors: Made from materials like ceramic, porcelain, or stone, offering durability and ease of maintenance.

- Vinyl Flooring: Provides a cost-effective, durable, and aesthetically versatile flooring solution.

- Carpet: Offers comfort, warmth, and noise reduction, commonly used in residential settings.

Components:

- Joists: Horizontal beams that support the floor load.

- Subfloor: The base layer over the joists, providing a stable platform for the floor covering.

- Underlayment: A layer between the subfloor and the finish flooring that can provide soundproofing, moisture protection, and a smooth surface for the finish material.

- Finish Flooring: The visible, top layer of the flooring, chosen for aesthetic and functional properties.

Deterioration of Timber

Introduction to Timber Use in Building

Timber is a crucial material in the building industry, valued for its strength, flexibility, and visual appeal. Nonetheless, it is prone to various degradation forms that can affect its structural integrity and lifespan.

Reasons for Timber Degradation

1. Biological Factors:

– Fungi: The primary culprits of timber decay are wood-destroying fungi, which need moisture to survive. The most harmful varieties include brown rot, white rot, and soft rot.

– Insects: Termites, wood borers, and carpenter ants can infest timber, eating the wood or utilizing it for their nests.

– Marine Organisms: In aquatic and marine settings, species like shipworms and limnoria can deteriorate wooden structures.

2. Environmental Factors:

– Moisture: Excess moisture from precipitation, humidity, or leaks can foster fungal growth and cause wood to swell, whereas dry conditions can lead to shrinkage.

– Sunlight and UV Radiation: Extended exposure can break down the wood’s lignin, causing surface damage and reduced strength.

– Temperature Changes: Frequent expansion and contraction can crack the wood and weaken its structure.

3. Chemical Factors:

– Acidic Conditions: Acidic environments can speed up wood degradation.

– Salts: Near the coast, salts can attract moisture, leading to decay.

– Pollutants: Pollutants like sulfur dioxide can chemically react with wood, causing further deterioration.

Forms of Timber Degradation

1. Fungal Decay:

– Dry Rot: This occurs when fungi spread moisture from wet to dry areas, impacting extensive timber sections.

– Wet Rot: This happens when wood remains in constant contact with water, causing localized decay.

2. Insect Damage:

– Termites: These insects can significantly damage structures by consuming the wood.

– Wood Borers: The larvae of certain beetles burrow through wood, leaving noticeable holes and tunnels.

3. Physical Deterioration:

– Cracking: Environmental stresses such as changes in temperature and humidity can cause timber to crack.

– Warping: This occurs when wood dries unevenly, causing it to twist or bow.

4. Chemical Damage:

– Corrosion of Fixings: Chemical interactions between timber and metal fasteners can lead to corrosion, compromising joint strength.

Preventive Actions and Treatments

1. Design and Building Techniques:

– Proper Design: Structures designed to prevent moisture accumulation and promote air circulation can avert decay.

– Material Choice: Opting for naturally resistant or treated wood can improve longevity.

2. Chemical Treatments:

– Preservatives: Chemicals can safeguard timber against biological threats and enhance its durability.

– Fire Retardants: These treatments help reduce timber’s fire risk.

3. Maintenance Practices:

– Regular Checks: Identifying problems early can prevent extensive damage.

– Repair and Replacement: Timely fixing or replacing damaged wood can stop further degradation.

4. Environmental Management:

– Moisture Control: Efficient drainage and barriers can maintain dry conditions.

– Ventilation: Proper air flow can prevent moisture buildup and fungal development.

Implications of Timber Deterioration in Building

Timber deterioration not only compromises structural safety and stability but also increases maintenance costs and reduces the lifespan of building components. Recognizing and managing decay risks are vital for sustainable construction practices.

Conclusion

While timber is a valuable asset in construction, it demands careful management, treatment, and upkeep to mitigate deterioration. Integrating an understanding of deterioration causes and types with effective preventive measures can greatly improve the durability and functionality of timber structures.

Hand Tools

Introduction to Hand Tools

Definition and Significance

Hand tools are operated manually, without reliance on external power sources like electricity. In the realm of Building Technology, these tools are indispensable, facilitating a broad spectrum of activities from initial groundwork to final detailing. They offer precision, control, and functionality in situations where using machinery is not feasible.

Evolution of Hand Tools

Historically, hand tools have been instrumental since ancient times, beginning with rudimentary materials such as stone and wood, advancing to contemporary materials like high-grade steel and composites. This evolution has mirrored progress in technology and material science, fostering the creation of more specialized tools that enhance both efficiency and safety.

Types of Hand Tools

– Cutting Tools: These include tools such as saws and chisels, designed to cut materials.

– Gripping Tools: Tools like pliers and wrenches, used for holding and manipulating objects.

– Hitting Tools: Including hammers and mallets, these are used for impact.

– Measuring Tools: Crucial for accurate construction, including rulers, tape measures, and levels.

– Miscellaneous: Other tools, such as screwdrivers, are also categorized based on specific uses like fastening or finishing.

Materials Used in Hand Tools

– Steel: Predominantly used because of its strength and durability. Various grades and treatments of steel cater to different tools, enhancing sharpness, hardness, or corrosion resistance.

– Wood: Commonly used for handles, wood offers a comfortable grip and can lessen fatigue with prolonged use.

– Plastic and Composites: These materials are frequently utilized for handles or the main body of some tools like levels, providing durability and comfort while allowing for features like magnetization or improved grip.

Choosing the Right Tool

The selection of hand tools depends on the specific task, the material being worked on, and the required precision. It is essential to select well-made tools that are suited to the task to ensure both safety and efficiency.

Categories of Hand Tools

Cutting Tools

Common Cutting Tools

– Saws: Useful for slicing through wood, metal, or plastic, with types ranging from hand saws to hacksaws and coping saws.

– Chisels: Employed for sculpting or slicing through wood, stone, or metal, with wood chisels being particularly prevalent in carpentry.

– Knives: Utility knives serve as multipurpose cutters in construction, ideal for slicing materials like wallpaper and vinyl.

Uses

– Saws are chosen based on the material and the precision of the cut required, from basic rough cuts to intricate detailing.

– Chisels not only cut but also shape materials where meticulous material removal is necessary.

– Knives are crucial for precision work requiring a keen edge for neat cuts.

Maintenance

– Maintain sharpness of blades to avoid the hazards and inefficiencies of dull blades.

– Clean tools regularly to ward off rust and corrosion on metal parts.

– Store tools properly, ensuring cutting edges are protected to preserve sharpness and prevent accidents.

Safety

– Always select the appropriate blade for both the material and the type of cut.

– Utilize proper safety equipment, like gloves and safety glasses.

– Operate cutting tools in a stable and secure setting to prevent slips and inaccurate cuts.

Gripping and Prying Tools

Common Gripping Tools

– Pliers: Includes types such as needle-nose, slip-joint, and locking pliers.

– Wrenches: Tools like spanners and adjustable wrenches are used for manipulating nuts, bolts, and other fasteners.

– Clamps: Essential for securely holding materials in place during tasks.

Uses

– Pliers are handy for bending, twisting, cutting wire, and securing small items.

– Wrenches are vital for assembly and maintenance tasks, ensuring tight and secure fastenings.

– Clamps are indispensable in both woodworking and metalworking for secure placement, facilitating precise work without movement.

Maintenance

– Keep tools clean and dry to prevent deterioration.

– Lubricate moving parts to maintain smooth operation and guard against rust.

– Regularly inspect tools for wear or damage and replace them as necessary.

Safety

– Choose the correct tool for each task to avoid damage to both the tool and the workpiece.

– Maintain a firm grip and stable stance to prevent mishaps.

– Keep hands clear of the work area to avoid injuries like pinching or crushing.

Hitting Tools

Common Hitting Tools

– Hammers: Available in various weights and sizes, these are the most frequently used hitting tools.

– Mallets: Typically made of rubber or wood, used for delivering gentler blows to prevent damage to the workpiece.

– Punches and Chisels: Used alongside hammers to engrave, shape, or cut through tough materials.

Uses

– Hammers are utilized for driving nails, fitting components, forging metal, and demolishing objects.

– Mallets are vital in fields like carpentry, upholstery, and masonry for applying controlled force.

– Punches and chisels need accurate strikes to effectively shape or cut materials, especially in metalworking.

Maintenance

– Check handles for any signs of damage such as cracks or splinters and replace if needed.

– Maintain clean and smooth striking faces to prevent workpiece damage.

– Store hammers carefully to avoid harming other tools.

Safety

– Opt for a hammer that matches the weight and size required for the task.

– Protect eyes with safety goggles to shield against particles.

– Ensure a solid grip and proper posture to avert strain or injuries.

Measuring Tools

Common Measuring Tools

– Tape Measures: Flexible rulers crucial for measuring lengths in construction.

– Levels: Ensure that constructions are perfectly horizontal or vertical.

– Squares: Vital for verifying accurate angles, particularly in carpentry and framing.

Uses

– Tape measures provide quick and precise length measurements.

– Levels are essential for confirming the plumb and level status of structures, impacting their stability.

– Squares help in verifying right angles and ensuring uniformity during layout tasks.

Maintenance

– Maintain cleanliness and dryness of measuring tools to ensure their accuracy.

– Handle precision tools like levels with care to avoid impacts that could affect their accuracy.

– Regularly check tools for calibration to maintain accurate measurements.

Safety

– Handle tools carefully to avoid injuries from any sharp edges.

– Store tools securely to prevent accidental falls or damage to precision surfaces.

Assorted Hand Tools and Their Uses

Common Tools

– Screwdrivers: These are used for driving and removing screws with different head types such as flathead, Phillips, and Torx.

– Files and Rasps: Employed for shaping or smoothing materials like wood or metal.

– Wire Strippers and Crimpers: Crucial for electrical tasks, these tools are used to strip wire insulation and attach connectors.

Applications

– Screwdrivers are essential for the assembly, maintenance, and disassembly of components featuring screws.

– Files and rasps are used to remove minimal amounts of material, ideal for finishing or shaping tasks in metalworking and woodworking.

– Wire strippers and crimpers are vital for electrical tasks to ensure secure and safe connections.

Maintenance

– Keep screwdriver tips intact and free of rust. Worn screwdrivers can damage screws and decrease efficiency.

– Files and rasps should be cleared of any debris lodged between their teeth regularly.

– Maintain wire strippers and crimpers by keeping them clean and well-lubricated for optimal precision and functionality.

Safety Guidelines

– Use the correct screwdriver type and size to prevent slipping and potential injuries.

– Handle files and rasps carefully as their sharpness can lead to cuts if mishandled or improperly stored.

– When using wire strippers and crimpers, always ensure that electrical circuits are turned off to avoid hazards.

Safety Practices with Hand Tools

– Personal Protective Equipment (PPE): Wear suitable PPE like safety goggles, gloves, and ear protection as required by the task.

– Tool Inspection: Check tools for damage or wear before use to prevent failures that could cause injuries.

– Proper Use and Handling: Always use tools as intended, maintain a firm grip, and ensure body balance to avoid accidents.

Work Environment

– Maintain a clean, clutter-free workspace to minimize accidents.

– Ensure adequate lighting to clearly see the work area and tool handling.

– Properly store tools when not in use to protect them from damage and prevent injuries.

Training and Awareness

– Understand each tool’s function and operation to prevent misuse and related accidents.

– Be conscious of others when using hand tools and secure workpieces properly to avoid unintended movement and accidents.

Building Technology Applications

Construction Tasks

– Hand tools are crucial for various construction activities like framing, roofing, finishing, and repairs, chosen for their specific capabilities.

– Tools like hammers, nail guns, and measuring tapes are vital for framing to ensure accurate construction.

– Chisels and planes are used for precise woodworking tasks like fitting joints and smoothing surfaces.

Maintenance and Repair

– Routine building maintenance heavily relies on hand tools such as screwdrivers, pliers, and wrenches for mechanical and electrical repairs.

– Tools like pipe wrenches and pliers are necessary for maintaining plumbing systems, allowing tight connections and fixture replacements.

Specialized Construction

– Specialized construction tasks, such as those involving electrical wiring and plumbing, demand specific tools like wire strippers and pipe cutters, reflecting the variety of tools needed across different building trades.

Precision and Craftsmanship

– Hand tools are indispensable in achieving the high levels of precision and craftsmanship required in many facets of building technology, from accurate material cuts to meticulous surface finishes.

Advanced Applications of Hand Tools in Building Technology

Enhancements in Ergonomics and Efficiency

Hand tools are being increasingly engineered with ergonomic features to minimize user fatigue and injury, incorporating cushioned grips and light materials to enhance comfort and productivity. The design of these tools also prioritizes efficiency by incorporating multifunctional capabilities, allowing a single tool to perform multiple tasks and minimizing the need for carrying and switching different tools.

Precision and Customization in Tool Use

The customization of tools enables more precise operations, featuring adjustable wrenches for micro-adjustments and laser levels for exact accuracy over vast distances. Builders can also tailor their tool kits for particular projects or materials, which streamlines their workflow and improves results.

Future Directions in Hand Tool Development

Technological Enhancements

The integration of technology into hand tools, like digital measuring devices and intelligent detection systems, boosts accuracy and diminishes construction errors. New materials such as carbon fiber and ceramics are being utilized to make tools lighter and more durable.

Sustainability in Tool Manufacturing

Tool production is increasingly focusing on sustainability, with a commitment to durability and the use of recycled or eco-friendly materials. Manufacturing processes are also evolving to lessen environmental impacts by reducing waste and energy use.

Education and Training for Hand Tool Proficiency

Certification Programs

The rise of certification programs for specific tools and construction methods ensures that workers are skilled and current with the latest safety and operation standards. These certifications not only enhance individual competencies but also improve overall safety and efficiency on sites.

Continual Learning

Continuous education in hand tool use is essential, particularly as new tools and technologies are introduced. Workshops, online courses, and practical training are crucial for maintaining up-to-date skills. Training programs are increasingly incorporating VR and AR to simulate realistic scenarios safely.

Innovations in Safety

New hand tools include advanced safety features like non-slip grips, integrated safety covers for cutting tools, and automatic shut-offs for powered tools. Further innovations include gloves that interact with power tools to ensure safe operation and wearable technology that monitors tool use and user posture to prevent injuries and ensure proper maintenance and storage of tools.

Conclusion

Hand tools remain crucial in building technology for various construction, maintenance, and repair tasks. Their ongoing evolution reflects significant advances in technology, safety, and efficiency, continually shaping their role and effectiveness in the industry.

Fasteners, Adhesives and Hardware

Introduction to Fasteners

Fasteners are essential tools in construction, used to connect two or more objects mechanically. They are critical in building technology for providing structural stability, support, and evenly distributed loads. Popular fasteners include nails, screws, bolts, and anchors.

Fastener Varieties

– Nails:

– Common Nails: Appropriate for rough carpentry where durability outweighs aesthetics.

– Finishing Nails: Smaller heads for jobs requiring a clean finish.

– Box Nails: Slimmer than common nails, minimizing wood splitting.

– Roofing Nails: Broad-headed and short, perfect for securing roofing materials.

– Screws:

– Wood Screws: Sharp threads that easily penetrate wood.

– Machine Screws: Fully threaded for use with nuts or in tapped holes.

– Sheet Metal Screws: Designed to fasten metal to metal or other materials.

– Bolts:

– Carriage Bolts: Feature a smooth, domed head for a neat appearance.

– Hex Bolts: Often used with nuts, identified by their hexagonal head.

– Anchor Bolts: Ideal for fastening items to concrete.

– Anchors:

– Wedge Anchors: Base expands in concrete for a secure hold.

– Sleeve Anchors: Distribute the load over a larger area.

– Plastic Wall Anchors: Suitable for light-duty applications in hollow walls.

Selection Tips for Fasteners

– Material Compatibility: Select fasteners that match the materials to ensure a secure connection and prevent corrosion.

– Load Capacity: Evaluate the fastener’s ability to support the intended weight and type of load.

– Environmental Adaptability: Choose fasteners that are resistant to weather and corrosion for outdoor or humid environments.

Introduction to Adhesives

Adhesives play a pivotal role in construction by binding surfaces together and distributing loads across joints, enhancing support and filling gaps.

Adhesive Types

– PVA (Polyvinyl Acetate):

– Application: Best for bonding wood, paper, and fabric.

– Characteristics: Non-toxic, straightforward application, dries clear.

– Epoxy Resins:

– Application: Ideal for joining metals, plastics, and ceramics.

– Characteristics: Provides a robust, heat and chemical-resistant bond.

– Polyurethane Adhesives:

– Application: Effective for wood, foam, and glass.

– Characteristics: Flexible, waterproof, works well on uneven surfaces.

– Contact Cements:

– Application: Used with laminates, rubber, and in high-pressure situations.

– Characteristics: Instant bonding upon contact, requires precise application.

Choosing the Right Adhesive

– Surface Compatibility: The type of surfaces being bonded influences the choice of adhesive.

– Bond Strength: The necessary strength of the bond determines the selection.

– Exposure to Elements: Consider environmental factors such as UV, moisture, and temperature when selecting an adhesive.

Introduction to Hardware

Hardware refers to the metal tools and accessories used in the construction and finishing of buildings, including hinges, handles, brackets, and locks.

Hardware Categories

– Hinges:

– Butt Hinges: Standard for interior doors.

– Piano Hinges: Suitable for long doors or panels.

– Ball Bearing Hinges: Ideal for heavy doors or frequent use.

– Handles:

– Lever Handles: Typically used on doors requiring a push/pull function.

– Pull Handles: Standard on drawers and cabinets.

– Brackets:

– Shelf Brackets: Support shelves with options from decorative to functional.

– Angle Brackets: Offer structural support at corners.

– Locks:

– Deadbolts: Provide enhanced security for doors.

– Cam Locks: Commonly found on cabinet doors and panels.

Selecting Hardware

– Functionality: Ensure the hardware meets the functional requirements of the project.

– Aesthetic Fit: Choose hardware that fits the design aesthetics of the building.

– Longevity: Opt for durable materials and finishes suitable for the intended use and environmental conditions.

Conclusion

A thorough understanding of the appropriate use and selection of fasteners, adhesives, and hardware is crucial for the longevity and integrity of building structures. Each category serves specific purposes and requires careful consideration to ensure they meet the demands of construction projects effectively.

Site Work Operations

Introduction to Site Work Operations

Definition and Overview

Site work operations in building construction constitute the initial phase of a project, setting the stage for subsequent building and infrastructure development. This phase spans various activities, from the initial site survey and layout to grading and landscaping, which precedes the actual construction of buildings. The primary aim of site work is to establish a stable and ready base that supports the safe and efficient erection of structures.

Importance in Construction

Site work is essential as it impacts the safety, durability, and legal compliance of the construction project. Adequate site preparation guarantees that the foundations and structures are established on firm ground, have sufficient drainage, and are devoid of conditions that may lead to future damage or failures, such as soil instability or water accumulation.

Site Analysis and Preparation

Site Inspection

A comprehensive site inspection is indispensable before construction to pinpoint potential issues such as uneven terrain, water bodies, or contaminated soil. This inspection informs the planning process to address any identified risks.

Soil Testing

Soil testing evaluates the soil’s load-bearing capacity, composition, and other vital properties to determine the appropriate foundation type. These tests may cover soil density, absorption rates, and the presence of chemicals or pollutants.

Site Clearing and Excavation

Site clearing entails the removal of unwanted materials like vegetation, rocks, and debris. Depending on the project requirements, excavation can range from simple leveling to extensive digging for basements or subterranean structures.

Levelling and Grading

Following excavation, it is necessary to level and grade the site to ensure proper drainage and establish a flat base for laying foundations. This process involves modifying the land’s slope to channel water away from the construction site, thus preventing flooding and erosion

Foundation Work

Types of Foundations

The choice of foundation is dictated by the load it must support and the soil conditions. Common types include shallow foundations such as slab-on-grade and deep foundations like piles and caissons.

Foundation Layout

The foundation layout, which involves marking the foundation placement, is crucial for ensuring that building loads are appropriately transferred to the ground.

Excavation for Foundations

This step includes soil removal to the required depth for the chosen foundation type, which must be executed with precision to minimize soil disturbance.

Foundation Construction

Building foundations involves placing footings, installing reinforcing bars (rebar), and pouring concrete, adhering to engineering specifications to ensure structural safety and longevity.

Installation of Site Amenities

Temporary Site Utilities

Before the installation of permanent utilities, temporary setups for power, water, and waste management are essential to facilitate construction operations and crew support.

Safety Measures and Signage

Safety protocols necessitate the installation of fencing, signage, and other barriers to safeguard workers and the public. Signs may denote areas requiring hard hats, access restrictions, and other potential hazards.

Storage Facilities

Properly positioned on-site storage facilities are crucial for housing materials, tools, and equipment, ensuring they are accessible yet do not obstruct construction activities.

Drainage and Contouring

Efficient surface drainage is crucial to prevent water from pooling, which can damage the foundation and other structures. Techniques such as gutters, French drains, and sloped surfaces effectively channel water away from the construction site to designated drainage areas. Subsurface drainage systems, which include weep tiles and perforated pipes, are employed to manage water that infiltrates the soil, helping to reduce hydrostatic pressure on underground walls and foundations. Additionally, contouring the landscape to direct water flow enhances aesthetic appeal while addressing functional drainage needs and preparing the site for subsequent landscaping and outdoor features.

Substructure Construction

Substructure construction involves the installation of footings and piers. Footings are broad horizontal structures that spread out under the foundation walls or columns to distribute the load across a larger area. Piers are vertical, column-like structures that extend deep into the ground to support the building’s weight, particularly crucial in areas with unstable soil. Basement construction, which includes creating below-ground space, requires careful excavation, wall construction with adequate waterproofing, and considerations for controlling environmental factors such as humidity and temperature within the space.

Superstructure Construction

The superstructure encompasses all parts of a building above the foundation. Erecting the framework and placing columns are vital for defining the building’s structural integrity and layout. Materials used may include steel, concrete, and wood, selected according to architectural requirements and load considerations. Additionally, scaffolding provides temporary platforms for workers to operate at heights, while formworks are molds used to shape concrete into structural elements like slabs, beams, and columns, both engineered to safely bear loads during construction.

Roads and Pavements

The construction of roads and pavements begins with precise layout planning and excavation to the required depth, which ensures proper subgrade stabilization and drainage. The sub-base, constructed from compacted non-frost susceptible material, provides a stable surface for the base course that supports the final road or pavement surface. Materials such as asphalt, concrete, or paving stones are chosen based on traffic load and environmental conditions to ensure a durable and even surface.

Utility Installation

The installation of water supply systems involves laying pipes that must be frost-protected and placed at a sufficient depth to avoid contamination. Sewer systems require careful gradient management to ensure effective flow towards treatment facilities and properly sealed joints to prevent leaks and protect groundwater. Trenching for electrical and communication lines is executed carefully to avoid disrupting other utilities, ensuring the lines are encased for safety and reliability.

Safety Measures

Workers on construction sites are equipped with personal protective equipment, including helmets, gloves, boots, and high-visibility clothing, to protect against various hazards. Site-specific emergency procedures need to be developed, which include evacuation plans, first aid measures, and maintaining updated contact information for emergency services. Compliance with occupational safety and health regulations is mandatory to safeguard the well-being of everyone on the site.

Environmental Considerations

Erosion and sediment control measures are implemented to prevent soil erosion during construction activities and to contain sediments within the site boundaries. Efficient waste management involves sorting, recycling, or disposing of construction debris in environmentally responsible ways. Modern construction increasingly incorporates sustainable practices such as using recycled materials, optimizing resource use, and minimizing the carbon footprint.

Quality Control

Regular inspections and testing are crucial to ensure that construction meets the specified standards and is progressing according to plan. Compliance with local building codes and international standards is necessary to ensure the safety and durability of the structure.

Project Management

Effective scheduling and phasing of construction activities are essential for optimizing resource use and minimizing the project’s duration. Proper resource allocation, including manpower, materials, and machinery, is key to ensuring efficiency and cost-effectiveness. Continuous cost analysis and control are pivotal in keeping the project within budget without compromising on quality.

Legal and Regulatory Compliance

Adherence to building codes and securing all necessary permits and approvals before starting work is crucial to avoid legal issues and ensure compliance. Regular inspections by authorities ensure that construction activities adhere to legal and safety standards, maintaining the integrity and safety of the project.

Foundations

What is a foundation, and why is it necessary?

A foundation is a crucial part of a building’s construction, connecting the base of the structure to the ground. It ensures a stable base and evenly distributes the building’s weight across the soil.

Types of Foundations

Foundations are broadly classified into two types:

- Natural

- Artificial.

Natural Foundation & Artificial Foundation

A natural foundation is simply the prepared ground that supports the building after excavation. An artificial foundation, however, is a structure built between the building and the natural foundation to enhance stability. There are various types of artificial foundations, including:

Concrete Strip Foundation

This common type involves pouring continuous strips of mass concrete into trench bottoms to support load-bearing walls. These walls are positioned on the strips to evenly distribute the load from the walls, roof, and upper floors.

Piled Foundation

Used when the surface soil is weak, piled foundations transfer the building’s load deeper into the ground. They come in two forms: bored or displacement piles, which are concrete filled holes spaced at intervals, and driven or displacement piles, where tree trunks are hammered into the ground at intervals.

Deep Strip Foundation

A deep strip foundation involves a narrow trench dug by an excavator and filled with concrete up to ground level. While consuming more concrete, it reduces the need for masonry walls and timber trench support.

Pad Foundation

Pad foundations are standalone foundations that support columns or piers. A square pad spreads the load uniformly across the ground.

Raft Foundation

Suitable for soils with low bearing capacity or for buildings with lighter loads, raft foundations combine the foundation with the ground floor slab, reducing the need for separate foundation digs.

Stepped Strip Foundation

Adapting to sloped terrain, this shallow foundation minimizes excavation and below-ground wall construction by stepping horizontally with the slope. Each step’s height should not exceed the foundation’s thickness.

Materials Used in Foundations

The materials selected for foundation construction significantly impact its strength, durability, and resistance to environmental factors. Key materials include:

Concrete: Known for its strength and durability, concrete is extensively used in foundations. Reinforced concrete, which incorporates steel rebar, provides added support and resists both tensile and compressive forces.

Steel: Steel is commonly used as reinforcement within concrete foundations to enhance strength. It is also used in deep foundations as steel piles, offering a high load-bearing capacity.

Masonry: Stone and brick masonry are often used in shallow foundations, particularly in smaller residential structures. These materials are cost-effective and provide good thermal insulation, though they are generally weaker than concrete.

Design Considerations for Foundations

Proper foundation design is essential for a structure’s stability and durability. Important considerations include:

Soil Investigation: Soil analysis is crucial to determine the type and depth of the foundation. Testing provides information on load-bearing capacity, compressibility, water content, and other soil properties.

Load Considerations: The structure’s weight, including permanent (dead) loads and temporary (live) loads, influences foundation selection. The foundation must support these loads without excessive settling.

Water Table: High water tables can cause soil instability and affect foundation longevity. Foundations in such areas require waterproofing and drainage solutions to prevent water damage.

Frost Line: In colder climates, foundations must extend below the frost line to avoid heaving from soil expansion when frozen.

Construction Techniques for Foundations

Common techniques in foundation construction include:

Excavation: This initial step involves removing soil to make space for the foundation. The depth and width depend on the type and design of the foundation.

Formwork and Falsework: Formwork shapes the concrete in shallow foundations, while falsework provides temporary support for deeper foundations. Formwork materials such as wood, steel, and plastic are chosen based on the design’s complexity.

Pouring Concrete: After excavation and formwork, concrete is poured to establish a stable base. Proper mixing and vibration of concrete are essential to prevent air pockets that could weaken the foundation.

Curing: Curing allows concrete to reach its full strength. This process involves keeping the concrete moist for a specified period (typically 7–28 days) to prevent premature drying, which could cause cracking and reduced strength.

Common Foundation Problems and Solutions

Foundations can face various challenges due to environmental conditions, soil quality, and construction errors. Common issues include:

Settlement: Uneven settling can cause structural damage, such as cracks in walls and floors. Proper soil analysis and foundation design are critical to managing anticipated loads and reducing settlement risks.

Water Seepage: Water infiltration is common in areas with high water tables. Solutions include waterproofing membranes, drainage systems, and sealants to protect against water damage.

Cracking: Foundation cracks can arise from settling, poor curing, or thermal expansion and contraction. Reinforcing concrete, ensuring proper curing, and adding expansion joints can help prevent or reduce cracking.

Maintenance and Repair of Foundations

Regular maintenance helps foundations remain stable and safe. Key practices include:

Routine Checks: Inspect foundations for signs of cracking, water seepage, and settlement issues. Detecting issues early can prevent more severe damage.

Repair Techniques: Common repairs involve:

Underpinning: Extending the foundation to deeper, stable soil or rock to support added loads or correct settlement.

Piering: Installing piers or pilings under the foundation to stabilize or lift it in cases of significant settlement.

Crack Injection: Filling cracks with epoxy or polyurethane to prevent water intrusion and further structural damage.

Summary

Foundations are essential for the stability and safety of structures, with their design needing to consider factors such as soil conditions, load requirements, and environmental challenges. Choosing between shallow and deep foundations depends on soil stability and specific building needs. Regular maintenance and prompt repairs are key to preserving the foundation’s durability and the overall integrity of the building.

3 -4 -5 Method

Introduction to the 3-4-5 Technique:

The 3-4-5 technique offers a straightforward approach to verifying right angles through the use of a Pythagorean triple. This method is crucial in construction and carpentry to ensure the precise execution of right angles where necessary.

Understanding the Technique:

It is based on the Pythagorean theorem, which asserts that in a right triangle, the square of the hypotenuse (the side opposite the right angle) is the sum of the squares of the other two sides. The numbers 3, 4, and 5 form a Pythagorean triple that exemplifies this theorem.

Utilization in Construction:

Marking Right Angles: This technique is applied in the foundational layout of buildings to confirm the squareness of corners, which is essential for structural integrity. For example, accurately squaring the foundation of a house is fundamental to avoid future issues.

Evaluating Existing Constructions: It’s also useful for checking the squareness of pre-existing structures, offering a simple and effective measure that can be conducted with basic tools.

Implementing the 3-4-5 Technique:

Measure and Indicate: Begin at a corner, extend 4 units along one edge, and mark this point.

Mark Perpendicularly: Measure 3 units along the perpendicular edge from the same corner and mark it.

Check Diagonally: Connect the marks and measure the diagonal. A measurement of exactly 5 units indicates a perfect right angle.

Essential Tools:

- A tape measure or a sizable ruler

- A marking instrument, such as chalk or a pencil

For Enhanced Accuracy: Using larger multiples of the 3-4-5 set (like 6-8-10, 9-12-15) can improve accuracy, particularly on bigger projects, as they minimize errors caused by small measurement discrepancies.

Constraints: The 3-4-5 method effectively confirms right angles, but its success hinges on precise initial measurements and accurate tools. Any errors in these areas can lead to inaccuracies.

Example Problem

Scenario:

As a building technician overseeing the construction of a new shed, you employ the 3-4-5 technique to ensure the foundation is square. You’ve measured 6 meters on one side and 8 meters on the adjacent side from the same corner. What should the diagonal be to confirm a right angle?

8m A------------------B |\ | \ | \ | \ 6m \ 10m | \ | \ | \ | \ C--------D

- A is the starting corner point.

- AB is 8 meters long (along one side of the corner).

- AC is 6 meters long (along the other side of the corner).

- BD is the diagonal connecting the ends of the two sides, and it should measure exactly 10 meters to ensure that angle A is a right angle.

Answer:

By applying the 3-4-5 rule at double the scale (2×3=6, 2×4=8), the diagonal should measure 2×5=10 meters.

Therefore, the measurement between the two points should be precisely 10 meters to verify the angle is right.

This method not only confirms the geometric accuracy of the construction but also aids in maintaining the structural integrity by ensuring right angles are used throughout the project.

Concrete and Cement

Introduction to Concrete and Cement

Concrete is a composite material made up of fine and coarse aggregates bonded with a fluid cement that solidifies over time. Widely used in construction for its robustness and strength, concrete is typically reinforced with tension-resistant materials, such as steel.

Cement, particularly Portland cement, acts as a binding agent in construction. It sets, hardens, and adheres to other materials to bind them collectively. It is rarely used alone, but rather to bond sand and gravel together.

Types of Cement and Their Properties

There are several types of cement, each engineered for specific applications:

- Ordinary Portland Cement (OPC): Commonly used for general construction, this type of cement is suitable where no special properties are required.

- Portland Pozzolana Cement (PPC): This includes pozzolanic materials which enhance strength and environmental sustainability by reducing the clinker required.

- Rapid Hardening Cement: Known for setting quickly and achieving strength early, facilitating faster construction completion.

- Low Heat Cement: Reduces the amount of heat emitted during setting and hardening, ideal for large concrete structures like dams.

Manufacturing Process of Cement

The cement manufacturing process involves multiple steps:

- Extraction and Preparation of Raw Materials: The primary materials, limestone and clay, are extracted from quarries, crushed, and ground into fine particles.

- Blending and Milling: These ground materials are mixed and milled to achieve the correct chemical composition.

- Heating: The mixture is heated in a rotary kiln at about 1450°C to form clinker.

- Grinding of Clinker: The clinker is cooled and finely ground, with a small amount of gypsum added to produce cement.

Properties of Concrete

Concrete’s properties can vary, influenced by the mix ratio and additives used. Key properties include:

- Compressive Strength: A crucial indicator of concrete’s performance.

- Workability: The ease with which concrete can be mixed, placed, and shaped.

- Durability: Its resistance to weathering, chemicals, abrasion, and deterioration.

Mix Design, Proportioning, and Production of Concrete

Concrete mix design involves selecting and proportioning ingredients to produce concrete with the desired strength, durability, and workability cost-effectively.

Testing of Concrete

Various tests are performed to assess concrete, such as:

- Slump Test: Evaluates consistency and workability.

- Compressive Strength Test: Measures strength development, performed on cube or cylinder samples.

- Durability Tests: Determines concrete’s long-term performance against environmental challenges.

Uses of Concrete in Construction

Concrete is utilized in various forms and structures in construction:

- Buildings: Including residential and commercial structures.

- Infrastructure: Such as bridges, roads, tunnels, and dams.

- Specialized Constructions: Including sound barriers, swimming pools, and parking lots.

Environmental Considerations and Sustainability

Cement production is energy-intensive and a significant source of CO2 emissions. However, using recycled materials, alternative fuels, and enhancing process efficiency are advancing sustainability in the industry.

Aggregates

Aggregates are natural materials obtained from pits and quarries, encompassing gravel, crushed stone, and sand.

Types of Aggregates

Aggregates are essential construction materials with several main types:

- Sand: Typically obtained from riverbeds or produced by crushing hard rocks. It’s valued for its compacting properties and is a crucial component in mortar and concrete.

- Gravel: Composed of rounded or angular particles from riverbeds or quarries, gravel is ideal for drainage and serves as a coarse aggregate in concrete mixes.

- Crushed Stone: Created by mechanically crushing rock to produce angular, sharp-edged particles. This type is commonly used in high-strength concrete and as a stable road base due to its load-bearing capacity.

- Recycled Concrete: Made by crushing and reusing old concrete, this environmentally friendly option reduces landfill waste and minimizes the need for new raw materials.

Properties of Aggregates

Aggregates must meet certain criteria to support concrete’s structural integrity:

- Size and Gradation: Impacts concrete’s strength, workability, and durability. Proper gradation minimizes voids, reducing the cement requirement.

- Shape and Surface Texture: Rounded aggregates make concrete easier to work with, while angular aggregates form stronger bonds.

- Density and Specific Gravity: Heavier aggregates contribute to stronger concrete, while lighter ones are suited for applications requiring reduced weight.

- Absorption and Moisture Content: Aggregates with high absorption can weaken concrete by increasing its water demand.

Sourcing and Processing

The extraction of aggregates requires selecting appropriate sites and methods:

- Natural Aggregates: Often sourced from quarries, riverbeds, or seabeds. Quarrying involves drilling and blasting to break down rock.

- Manufactured Aggregates: Produced by crushing large rocks in mills, then sorted by size.

- Recycling: Demolished concrete is collected, crushed, screened, and possibly washed for reuse.

Role in Concrete

Aggregates contribute significantly to concrete’s properties:

- Strength: Aggregates bear most of the load in concrete, so their quality directly influences concrete’s strength.

- Workability: The size and shape of aggregates affect how easy the mixture is to handle and compact.

- Durability: High-quality aggregates resist weathering and chemical damage, extending concrete’s lifespan.

Mix Proportions

Concrete mix ratios vary depending on the application:

- Standard Mixes: A typical mix ratio is 1:2:4 (cement: sand: coarse aggregate), suitable for non-load-bearing structures.

- Strength-based Mixes: Ratios like 1:1.5:3 provide stronger concrete, ideal for structural elements.

Testing of Aggregates

Quality tests are essential for aggregates:

- Sieve Analysis: Determines particle size distribution.

- Specific Gravity and Absorption: Measures aggregate density and water absorption capability.

- Crushing Value: Assesses resistance to crushing under gradual compressive load.

Environmental and Economic Impacts

Aggregate usage affects both the environment and construction costs:

- Environmental: Extracting natural aggregates can cause land degradation and habitat loss, while recycled aggregates help reduce these impacts.

- Economic: Aggregates make up a large portion of construction costs, so efficient use and recycling can lead to cost savings.

Regulations and Standards

Aggregates must meet specific standards:

- ASTM and EN Standards: Set guidelines for aggregate properties and testing to ensure safety and quality.

- Local Regulations: Different countries may enforce specific standards to ensure safety and protect the environment.

Note: If there’s a particular topic we haven’t covered/ any misleading information, please feel free to contact us on Instagram at: @globelearners